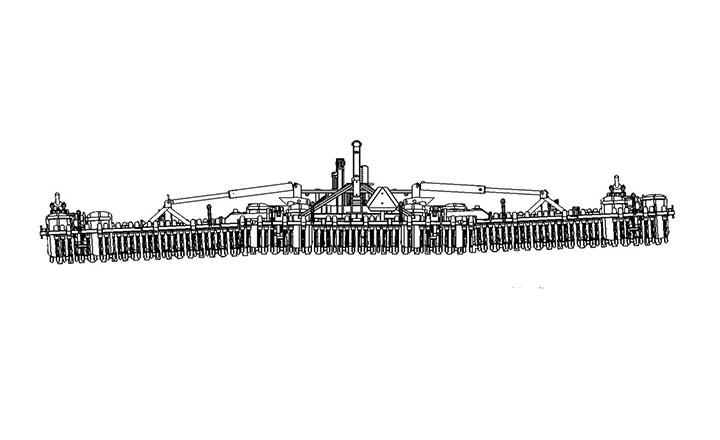

CULTIMAX ECO 800

CULTIMAX ECO 800 is a further development of the very popular CULTIMAX, which DALBO has produced for more than 15 years. The machine is a powerful 8-bullet seedbed cultivator, with a large working capacity, which is targeted for organic farming.

Technical data

CULTIMAX ECO 800

Concept

CULTIMAX ECO 800 ensures a good mixing of the soil, as

there is a large flow of soil and plant residues. At the same

time, stable and precise tillage is ensured partly by means of

powerful turnable wheels on each side frame and partly by

means of the adjustable drawbar.

Overrunning with CULTIMAX ECO 800 thus helps to significantly reduce the occurrence of weeds. Even strong types of weeds with taproots are reduced with the full cutting of the goose foot.

Standard equipment

CULTIMAX ECO standard equipment

-

8-row harrow with 210 mm goose foot tines

-

3-row harrow (rear) with 12 mm harrow tines

-

Hydraulic weight distribution

-

DUOFLEX System

-

Support wheel front: 200/60x14,5 10 PLY

-

Wheels 520/50x17

Tines

CULTIMAX ECO 800 has a tine spacing of 150 mm, and is mounted with a goose foot of 210 mm.

The large overlap ensures full cutting, and specially manufactured heavy-duty double-spring goose foot is eminent for handling weeds with tap roots.

The 54 teeth are distributed over a total of 8 rows, which ensure a very good flow through the harrow.

Harrow (rear)

The powerful harrow (rear) is equipped with 12 mm curved harrow tines, divided into 3 rows.

With as many as 3 rows, there is a very good chance that the soil is shaken from the roots of weeds and leaves an even surface.

The harrow has adjustable weight transfer through strong tension springs from the main frame to the rear harrow.

Wheels

CULTIMAX ECO 800 is fitted as standard with large wheels in size 520/50x17.

It provides a very large carrying capacity, as the large wheel assembly ensures accurate depth control via hydraclips - also in soft areas.

Hydraulic weight distribution & DUOFLEX

CULTIMAX ECO 800 is equipped with DALBO's well-known and well-tested hydraulic weight distribution, which ensures an even weight over the entire working width.

At the same time, the machine also has DUOFLEX. A system that ensures individual movement for each section, and thus optimal ground contact regardless of the contours of the ground.